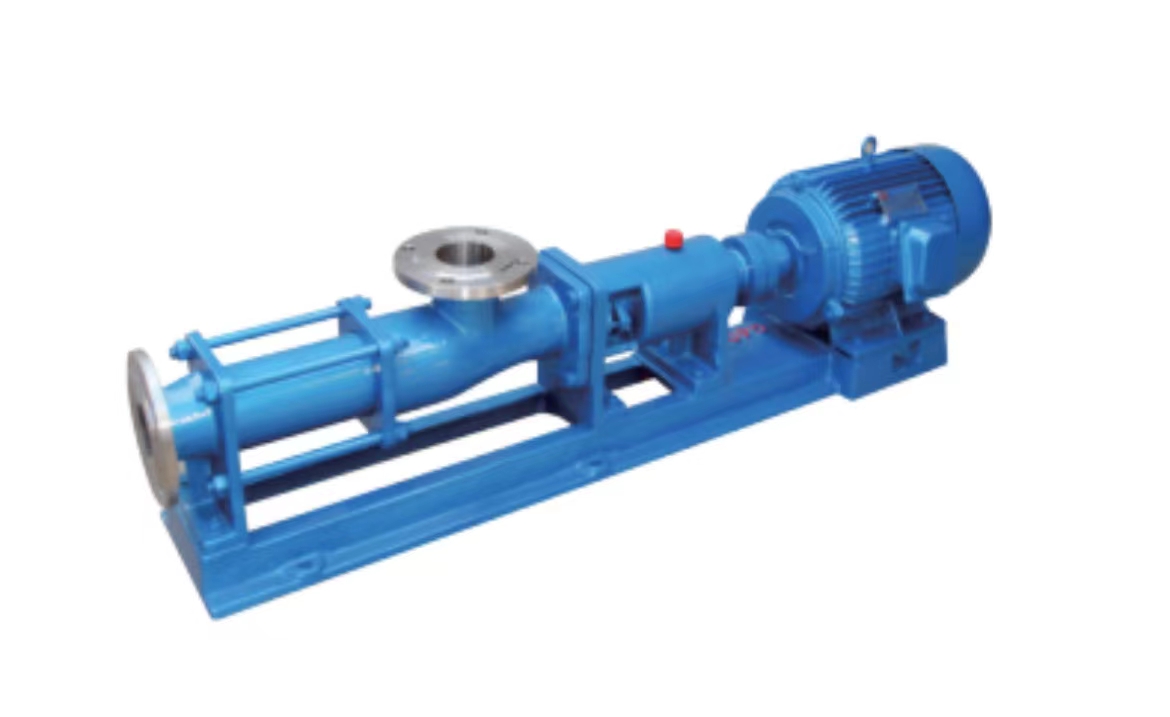

Screw mud pump

Screw mud pump is a new type of high efficiency, high pressure, long life of solid-liquid mixed transport machinery. It uses a single threaded rod, through the rotary movement to form a certain pressure in the sealing cavity, the suction at the suction tube formed after the medium. It has the characteristics of simple structure, reliable operation, convenient maintenance and so on. It can transport the medium with larger viscosity or containing solid particles.

Screw mud pump is a new type of high efficiency, high pressure, long life of solid-liquid mixed transport machinery. It uses a single threaded rod, through the rotary movement to form a certain pressure in the sealing cavity, the suction at the suction tube formed after the medium. It has the characteristics of simple structure, reliable operation, convenient maintenance and so on. It can transport the medium with larger viscosity or containing solid particles.

Screw mud pump is mainly composed of stand and rotor:

1. The frame includes stator body (including spindle and end cover), bearing seat and sealing chamber.

2, the rotor is composed of a main shaft and impeller.

1. Stator

(1) The stator body is equipped with a main shaft and end cover (fixed with bolts), and a connecting plate is installed at each end to support the bearing seat at both ends; On both sides

A pair of knurled keyways are provided for mounting rolling bearings.

(2) There is a sealing ring groove and a check valve between the end cover and the main shaft; The side plate is provided with two holes for the oil seal pressure ring; There are vent holes under the side plate.

(3) The sealing chamber is provided with lubricating oil passage and oil cup groove (for adding lubricating oil); The oil outlet at the lower part is connected with the oil outlet line and provided with overflow prevention

The device.

2. Rotor

(1) There are two spiral grooves on the rotating body in order to place the impeller (fixed on the rotor with a pin); Each blade is arranged in two spiral grooves, the outer diameter of the blade is equal to the diameter of the pump;

Flat washers are installed on both sides of each blade to prevent friction from damaging the blade surface

(2) The tip of the blade is in the shape of an eccentric sleeve, which fits in with the top of the other blade. When rotating, the two blades will produce a certain centrifugal force and squeeze and deform each other, thus playing the role of self-cleaning.

(3) The central position of the rotor is equipped with a bushing dynamic ring and a static ring, its role is to prevent medium leakage and leakage and balance the gap between the inner and outer walls.

(4) The foreign side of the moving ring is the static ring, that is, the auxiliary impeller, which supports it

The function of rotating part can make the whole rotor and moving ring keep good lubrication state. (ailerons)

(5) Fill the pit on the moving disk to increase the friction resistance

To reduce power consumption.

(6) Because of the bad working conditions of this kind of equipment, it is required to be Bei

High wear resistance and high temperature and corrosion resistance, (interlining

Screw type mud pump features